About PigeonWorks

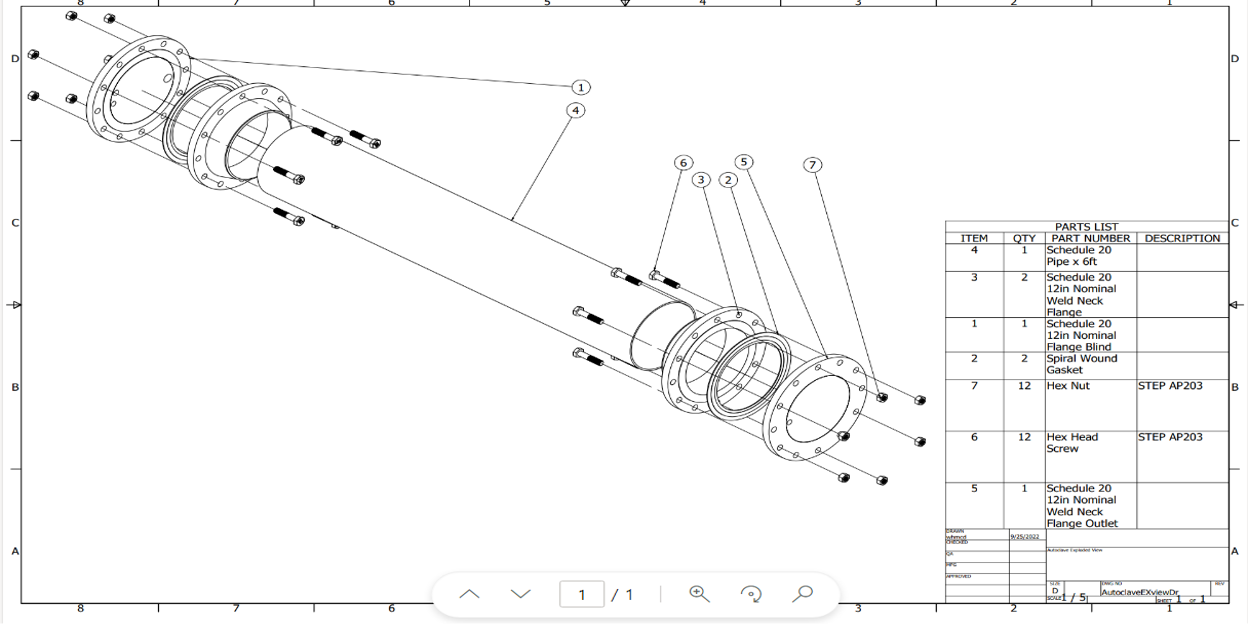

PigeonWorks is a special projects division of Raider Aerospace, and focuses on aerospace-related projects that don’t fall under Pegasus or Space Raiders. The current PigeonWorks flagship projects include the Liquid Rocket Engine, Hybrid Rocket Engine, Industrial Autoclave and High-Speed Rocket. The Liquid Engine team was a senior design project in the 2024-2025 year that RAS members completed. It was adopted by RAS and this year, the goal is to improve on the previous system and research alternate design posibilites. The Hybrid Engine Design team is focusing on manufacturing the system and getting some fires done this year. The Industrial Autoclave team is building from the ground up an autoclave that will allow for the manufacturing of carbon fiber composites that the entire society is able to use. The drone team is beginning this year and hopes to develop new vehicles that accomplish different goals, with the initial goal being a 200 mph drone.